Radiator Restoration – Our Recoring Process

The complete restoration of a flat head radiator from start to finish. It shows just how involved the process is to give the customer the absolute best product.

Our restoration process starts with a careful visual inspection. Next, is a thorough cleaning using our boil out tank or steam cleaner. The unit is completely disassembled and repairs made to tanks, rails, or other parts. The core is measured and a replacement ordered. The unit is reassembled using lead-free solder for copper brass units. It is pressure tested to ensure there are no leaks, painted, and returned to the customer.

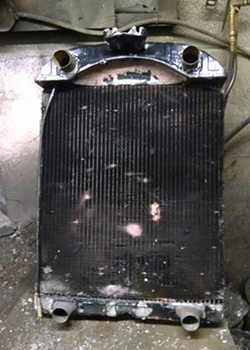

Radiator ready for disassembly, sand blasting and cleaning..

The final product complete,painted and ready for delivery.

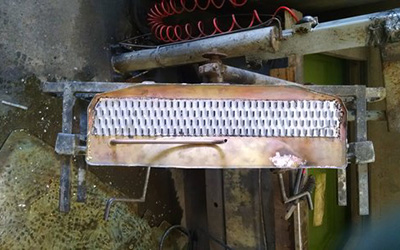

Side rails and tanks removed.

Side rail needing a better repair.

Total disassembly of all parts for inspection. Original top header removed to graft to the new core to maintain originality.

Grafting of the old header starting.

Cutting and forming the header.

The final set before solder.

Top tank being soldered in place.

Bottom tank ready for solder.

Side rail repaired and primed.

The final product complete,painted and ready for delivery.